|

| Puna Noni Juice |

|

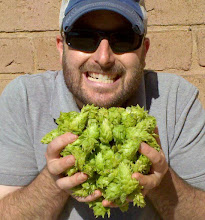

| Noni Fruit, Morinda citrifolia |

Puna Noni Sour

|

Specialty Beer

|

BJCP:

23A

|

Date: 12/20/2011

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Type: All Grain

|

Brewer: Sean

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Batch Size: 5.00 gal

|

Asst Brewer:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Boil Time: 90 min

|

Equipment: Chillindamos Brewhaus

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Original

Gravity: 1.061 SG

|

Measured Original Gravity:

1.059 SG

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Est Final Gravity:

1.017 SG

|

Measured Final Gravity:

1.010 SG

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Estimated Alcohol by Vol:

5.9 %

|

Actual Alcohol by Vol: 6.4 %

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IBUs (Tinseth’s):

38.1 IBUs

|

Est Color:

14.3 SRM

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Total Hop Weight: 3.80 oz

|

Calories: 196.2 kcal/12oz

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description: The noni juice is dark brown and very aromatic. The flavor and aroma are hard to describe since I haven't had anything like this before. Definitely funky! Should put most recipes found in "Radical Brewing" in the tame category.

I'll categorize this brew in BJCP Category 23 - Specialty Brew for its unusual and exotic fermented fruit ingredient and no definitive baseline style. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mash Type: Single Infusion, Medium Body, No Mash Out

|

Total Grain Weight:

12 lbs 3.2 oz

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sparge Temperature:

168.0 F

|

Pre-boil Volume:

5.95 gal

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Primary: 14.00

|

Primary Temperature:

65.0 F

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Secondary:

365.00

|

Secondary Temperature:

60.0 F

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Days in Tertiary: 7.00

|

Tertiary Temperature:

65.0 F

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbonation Type:

Keg

|

Volumes of CO2: 2.3

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure/Weight:

12.54 PSI

|

Carbonation Used:

Keg with 12.54 PSI

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Keg/Bottling Temperature:

45.0 F

|

Storage Temperature:

60.0 F

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Notes: Added noni juice directly to the primary just before pitching WLP565. Saison I yeast was choosen for its known ability as an underachiever leaving food behind for the sour blend to do its work. 60 seconds of oxygen via diffusion stone also applied prior to pitching. No yeast starter used, single vial only. Started ferment at 65°F and insulated well to allow free-rise. I will not ramp up the temperature like most saison fermentation profiles. Instead, I will let 565 do what it can before racking to secondary and pitching two vials of WLP655 Belgian Sour Mix I. Then, it will sit for a year.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Created with BeerSmith

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rodríguez, Wilfredo. Noni Fruit (Morinda Citrifolia).jpg. 2008. Photograph. Morinda Citrifolia. Wikipedia.org, 15 Oct. 2008. Web. 21 Dec. 2011.

WHOAH, SEND ME A BOTTLE! ; )

ReplyDeleteSean, you got it. I know you like the funk and this should prove to be a wild experiment. A visit to Portland is on my list.

ReplyDeleteSounds neat. I'll have to bring over a few of my sours and I'll want to try this one.

ReplyDeleteHey Jeff, I can now brew up to 20 gallons so filling that barrel shouldn't be difficult. Will only need to test the barrel for bad bugs like acetobacter.

ReplyDeleteAlright you mentioned you'll be keeping this beer in bulk storage for about a year. This is something I've always been curious about, how do you prevent spoilage and especially oxidation over that amount of time? I know how I do it with my wine, but with beer you don't have the higher alcohol content to ward off spoilage bugs and you can't use SO2. Is this one of those times in beer making you are extra diligent in cleaning and sanitizing and then just hope the beer gods are kind to you?

ReplyDeleteAlso, I don't know if you've seen this trend in California but we are seeing craft distilleries pop up in the midwest. They are using smaller oak barrels (there are cooperages in MO and MN)those smaller barrels would be perfect for beer.......just sayin

Aging beer has its own tricks just as with wine. Along with good sanitation, beer has alcohol and hops creating less ideal circumstances for undesirables. Aging a big beer like a barleywine, extensive amounts of hops should be used similar to sulfite management in wine. In a beer like this, additional flora added will also out compete any critters that may slip by sanitation defenses. Wild saccharomyces, brettanomyces, and bacteria strains pediococcus and lactobaccilus are being added to this beer. These species will stay in solution for quite some time and also change the pH (lactic acid) of the beer, inhibiting other undesirables. Another bonus with brewer's yeast and friends is their ability to scavenge oxygen. For beers that need extended aging like the Burton Ale I brewed last year (needs another year), transferring to keg and partially or fully carbonating can be a great strategy. Cheers!

ReplyDeleteOh, and craft distilleries. I know of only two and they tell gruesome stories of getting in business. The laws are probably different otherwise I think we'd experience the same.

ReplyDeleteThere's at least one place in town that sells smaller sized barrels but also a number of breweries offer spent barrels to homebrewers. They are usually full barrels though!

I have a 15 gallon barrel from Dave's days with zinfandel. Sadly, it has had water in it for years. Hoping to heat sanitize it but will need to check for nasties before use.

If you have access to a boiler you could setup a steam system for Dave's barrel. I've heard of wineries using ozone as a sanitizer........

ReplyDeleteI'm hoping to setup a tour for my winemaking club at The Barrel Mill cooperage in MN this summer.......secretly I'm hoping that if I get a group order I'll get a discount. I'll let you know if something pans out.

Merry Christmas!

You guys are welcome to stay with us any time! Although I might not be here for too much longer, so we should talk about you visiting sooner than later. We have plans to move to Ohio by summer or fall at the latest.

ReplyDeleteWhy is it that when you want WLP565 to dry out your saison, it stops at 1.015. And when you plan on conditions being less ideal, it chews down to 1.007!? It didn't taste sour going into secondary but I have a feeling there was some Puna Noni flora also working the fermentation. It is now in secondary with the Belgian Sour Mix.

ReplyDelete