My wife keeps my yeast as frozen stock in her laboratory. With a few days notice, she pulls a loop from the frozen stock and reinstates them in an agar plate. From there, she scrapes the yeast from the plate to a glucose vial.

In two days time, she brings home the vial to step-up to a 1L starter. This time, she also brought home the yeast plate to scrape for more cells.

Not many homebrewers have a PhD in the house to do this kind of stuff. It certainly saves cost per batch and it is very convenient!

I use a wide-mouth 1L erlenmeyer flask to step-up the yeast count and increase viability for pitching. In the flask are a few hop pellets, a pinch of yeast nutrient and a magnetic stir bar. The wide-mouth flask and a few hop pellets help reduce the chance of a boil over. In a measuring cup is 1/2 cup of dried malt extract and filtered water. I warm this up to near boiling in the microwave. This also helps reduce the chance of a boil over.

Together, I find 850ml to work best. 900 gives me less time to take preventative measures if a boil over is occurring (are you getting the theme here yet?). The largest challenge is bringing it up to a boil very carefully. When the wort begins to boil, ease off the heat to medium and allow to boil for 20 minutes for sterilization. (

Excuse our gross college stove! I'm sure a little of that comes from boil-overs from yeast starters but mostly from my lovely makinamess wife!)

After 20 minutes of boiling, I immediately cover the flask with aluminum foil and allow to cool on the stove top for about 5 minutes. I then immerse the flask in cool bath of water until room temperature.

When the flask is room temperature, I pitch the entire contents of the yeast vial in the flask and allow the stir plate to provide oxygen and consistent yeast-to-sugar contact.

24 hours on the stir plate turns the starter color from a malty brown to a yeasty beige, ready for pitching and immediate fermentation. I always place a damp towel between the starter and my stirrer since it generates a bit of heat.

Below is the end of the top row. This is the centennial hop that tends to grow best. It has just started to flower so this should be a good season for centennial. Notice the next hop mound next to the pole that doesn't have a vine long enough to train yet. I'll be checking up on them in a couple of weeks.

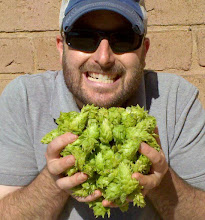

Below is the end of the top row. This is the centennial hop that tends to grow best. It has just started to flower so this should be a good season for centennial. Notice the next hop mound next to the pole that doesn't have a vine long enough to train yet. I'll be checking up on them in a couple of weeks. Below is chinook! As always, this hop loves it here and starts its season already producing. It should be ready for a first harvest mid July. I can typically continue harvesting until October from these vines. The bottom row is having difficulty establishing itself mainly due to some pest that likes to chew on the first vines.

Below is chinook! As always, this hop loves it here and starts its season already producing. It should be ready for a first harvest mid July. I can typically continue harvesting until October from these vines. The bottom row is having difficulty establishing itself mainly due to some pest that likes to chew on the first vines.